In the high-stakes environment of manufacturing, making data-driven decisions is imperative for procurement officers and business owners. One crucial yet often neglected aspect in the realm of product development is the creation of new tooling for specialized items like tin boxes. Traditionally, this involves a substantial investment with no guarantee of the quality of the end product. However, there exists a more financially prudent and risk-averse alternative: 3D Plastic Mock-Ups.

Creating new tooling for items such as tin boxes necessitates a significant financial outlay. This has long been considered a necessary yet risky investment, especially for companies specializing in top-quality, customizable products.

The traditional approach doesn’t provide for a preliminary quality inspection, placing the brunt of quality assurance post-production. Discovering errors at this stage can necessitate costly modifications or even complete retooling.

Given the inherent complexities of new tooling and subsequent manufacturing steps, delays are often inevitable. These disruptions can lead to missed peak sales seasons, affecting the bottom line adversely.

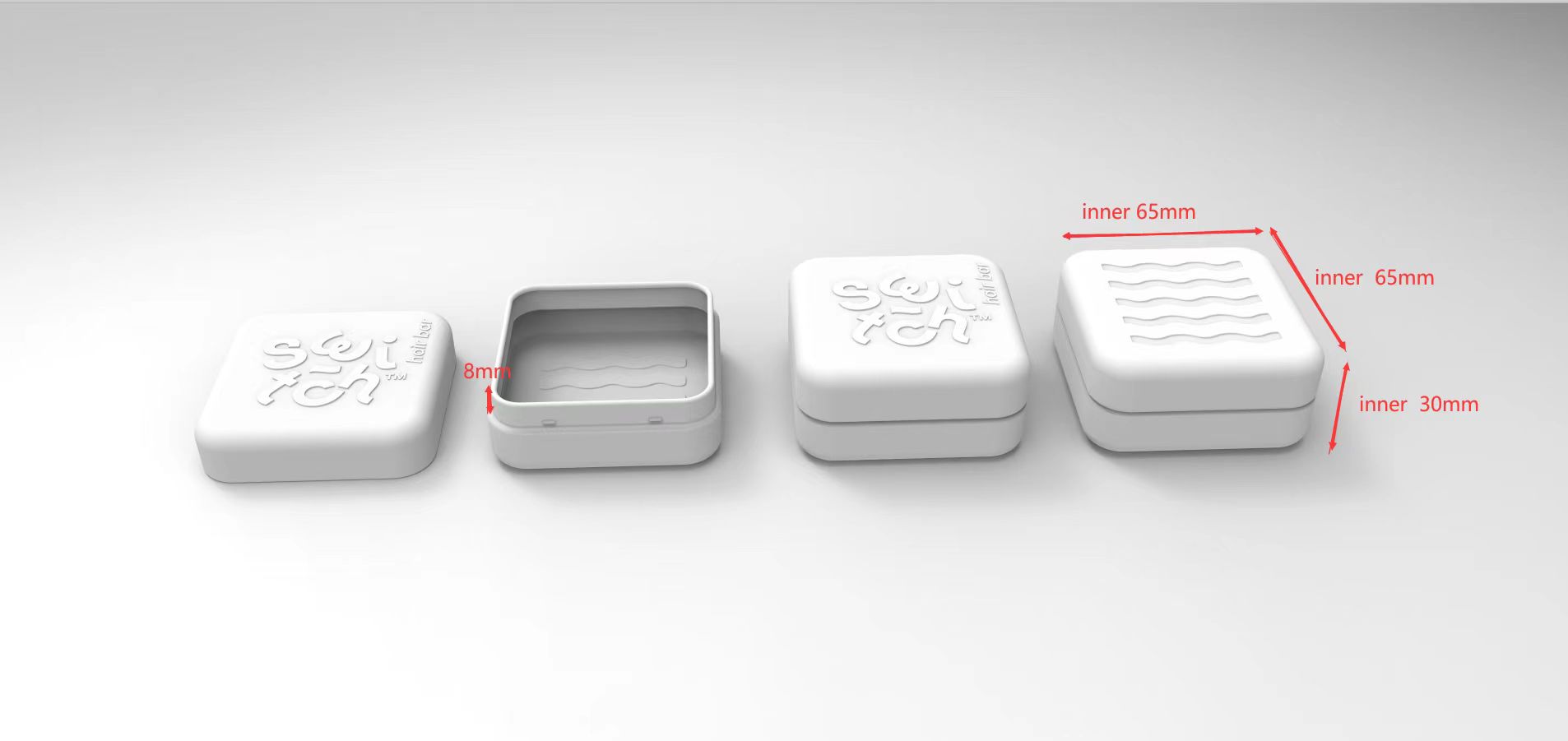

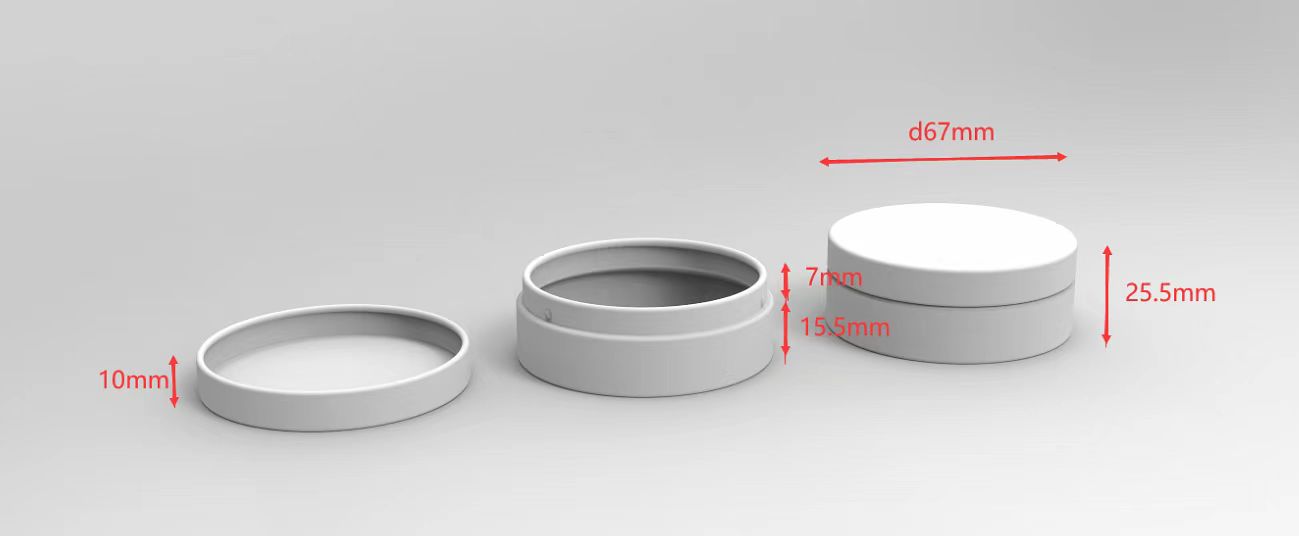

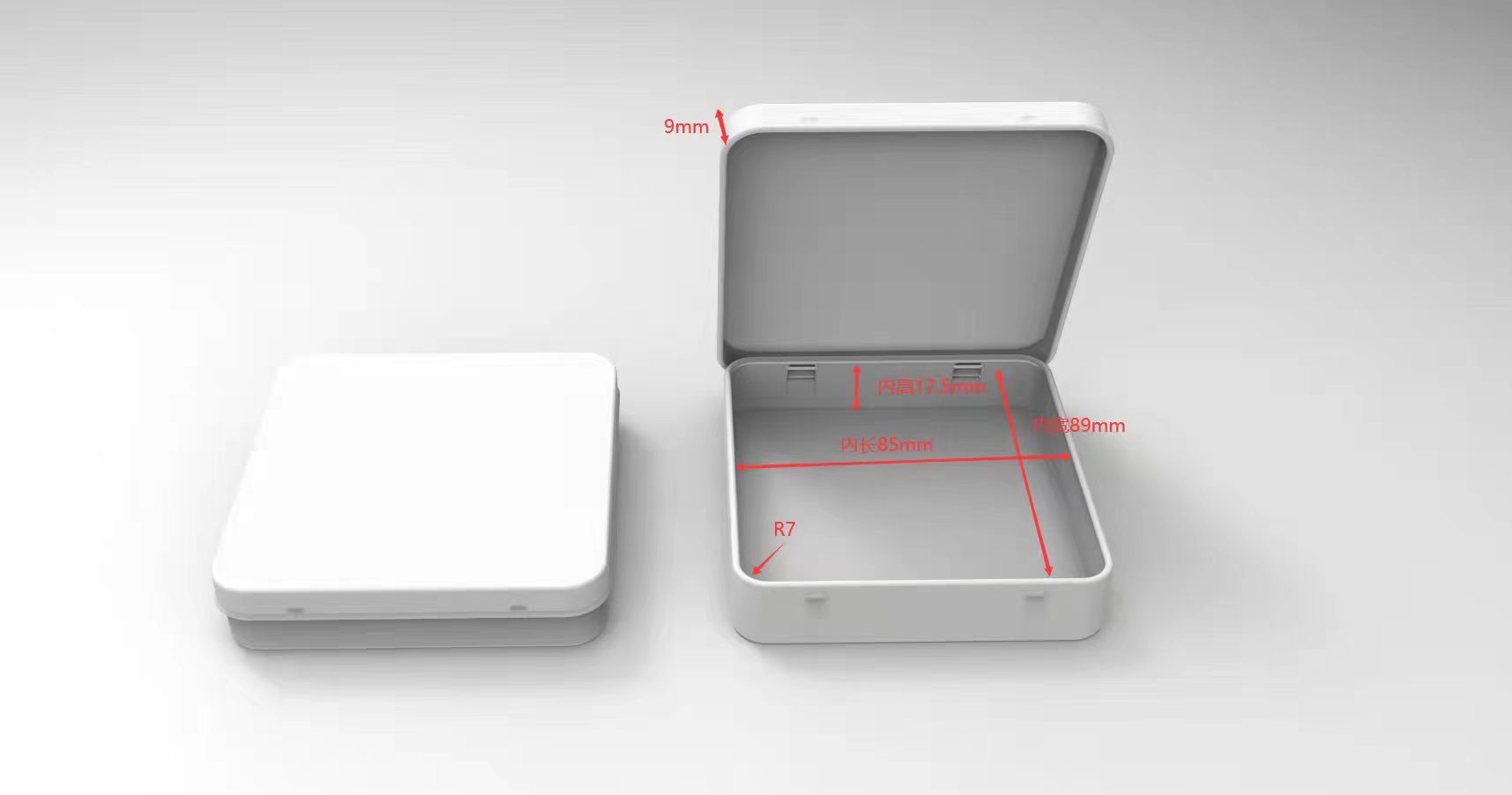

Opting for a 3D plastic mock-up before moving to the tooling stage can result in considerable cost savings. With an average cost of about USD 150.00—which can be deducted from subsequent orders—this option is particularly appealing for businesses that are sensitive to both quality and cost.

3D plastic mock-ups afford an opportunity for early-stage quality inspection. This enables procurement officers and business leaders to identify and rectify design or structural flaws before they escalate into more significant issues.

The turnaround time for creating a 3D plastic mock-up is generally much shorter compared to traditional tooling. This accelerated timeline can be a strategic advantage, enabling businesses to capitalize on peak sales periods.

Consider the example of a diamond-shaped tin box. A white 3D plastic mock-up was initially produced for quality and structural validation. Following client approval, the final red diamond tin box was manufactured, meeting and exceeding the client’s quality expectations.

In the context of tin box manufacturing, 3D plastic mock-ups present an efficient and cost-effective alternative to traditional tooling methods. By incorporating this step into your sourcing and procurement processes, you stand to gain in terms of quality control, speed to market, and overall cost-efficiency.

For any queries or additional information, you are welcome to reach out to us via lily@tdtin.com