Surface treatment is not just an aesthetic consideration when it comes to tin boxes; it plays a critical role in enhancing the product’s overall quality, longevity, and market appeal. This article aims to provide procurement officers, especially those dealing in high-volume B2B transactions, with an in-depth understanding of the various surface treatment options available for tin boxes.

Surface treatment for tin boxes is not just about achieving a visually pleasing finish. It serves several practical purposes such as corrosion resistance, improved adhesion for labeling, and ensuring the container is suitable for food storage or other specific applications. For B2B buyers, the selection of an appropriate surface treatment can significantly impact the product’s performance and, consequently, consumer satisfaction.

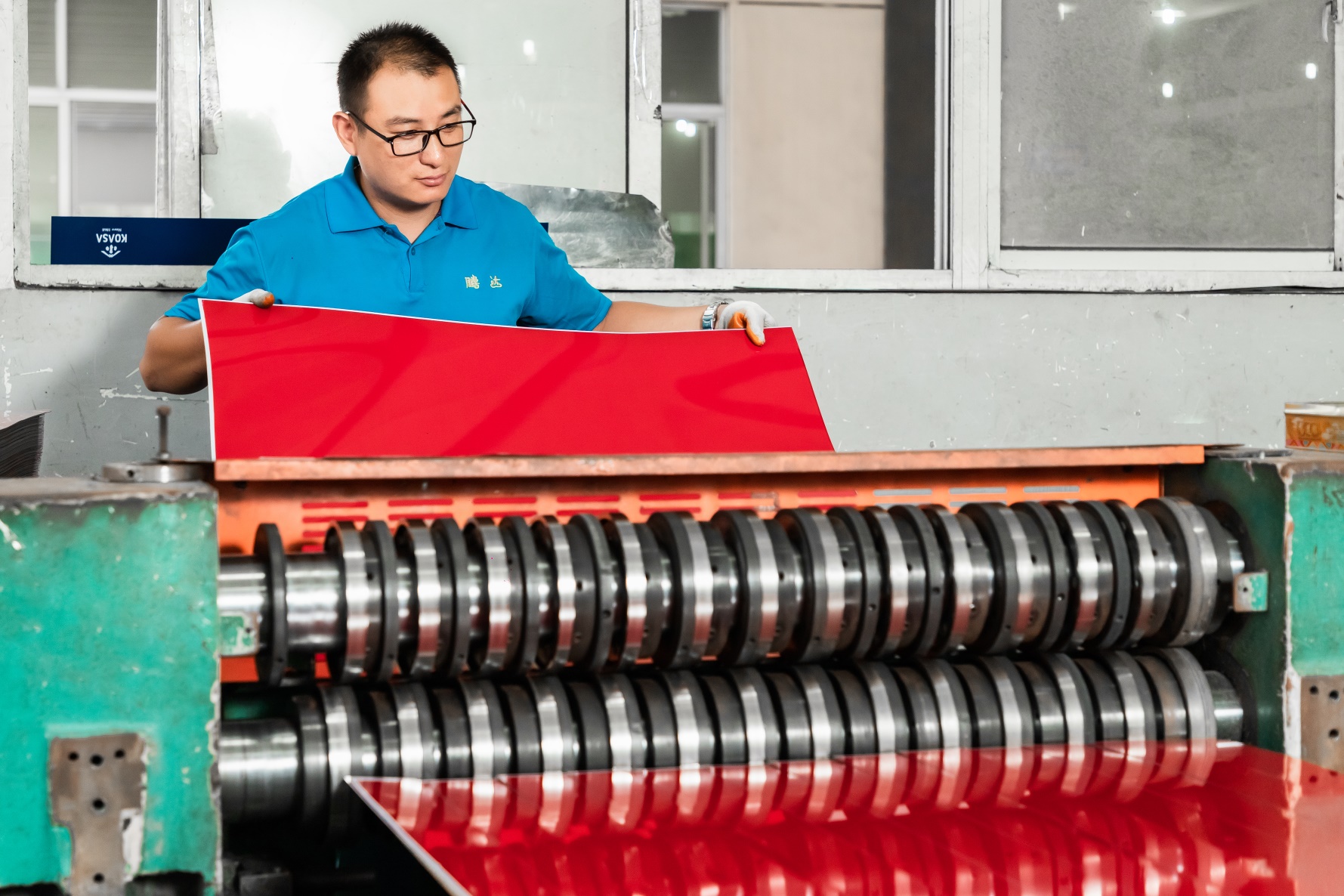

Varnishing involves applying a clear coat to the tin box, providing it with a glossy or matte finish. This technique enhances the aesthetic appeal and offers a certain level of protection against corrosion and abrasion.

Similar to varnishing, lacquering involves the application of a clear or colored coat. However, lacquers are typically harder and more durable, making them more suitable for boxes that will undergo significant handling.

Different treatments may be more or less effective depending on the material of the tin box. Therefore, understanding the material’s properties is essential in selecting the most appropriate surface treatment.

Surface treatment can add to the overall cost of the product. It’s crucial for procurement officers to strike a balance between quality and cost-effectiveness.

For B2B transactions, quality inspection and certification are often mandatory. Certificates from reputable organizations can vouch for the quality of the surface treatment, ensuring it meets industrial and international standards. In this context, it’s vital to be vigilant for any instances of certificate fraud.

Efficient logistics and flexible payment methods can have a substantial impact on the procurement process. Considering your supply chain logistics is vital when sourcing tin boxes with specific surface treatments. Streamlined logistics can help avoid delays that could lead to missed peak sales seasons, a significant concern for many B2B buyers.

Selecting the right surface treatment for your tin boxes is an essential part of the procurement process. The decision can affect not only the visual appeal of the product but also its performance, cost, and ultimately, the satisfaction of your end-users. Given the complexities, a detailed analysis that takes into account quality, logistics, and payment methods is crucial for making an informed decision.

We hope this comprehensive guide has provided valuable insights into the importance of surface treatment in tin boxes and will assist you in making informed purchasing decisions.

For any further queries, please feel free to contact us at Tengda, where quality meets expertise.

By understanding the various facets involved in surface treatment, you are better equipped to navigate the challenges and opportunities it presents. Thank you for reading, and we look forward to assisting you in your next procurement endeavor.